Laser Spectroscopy and

Nanoparticle Research

at The University of Texas in Austin

Nanoparticle Research

at The University of Texas in Austin

Magnetostrictive Actuators

Giant magnetostrictive (GMS) compounds such as Terfenol (TbFe2 ) or Terfenol-D (TbxDy1-xFey) are commonly used in actuators and sensors that require a fast response and large actuation strains. Thin films (<5µm) of GMS materials are now produced routinely using methods such as sputtering.

However, many useful devices such as micropumps, microvalves, and microactuators for applications such as ink-jet printer heads, optical beam defectors, and ultrasonic devices require thicker coatings (5-100µm) to develop larger displacements. Thus, there is still a great need for a method of fabricating high-quality, magnetostrictive thick films and a method for directly writing them as patterns onto a substrate.

Our LAM method combined with supersonic jet deposition is a straightforward adaptation method for producing nanocrystalline magnetostrictive films and results in amorphous films or films with a very small grain size (<10 nm). We microscopically characterize both the nanoparticles that were deposited and the films after deposition using electron microscopy and SQUID magnetometry.

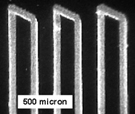

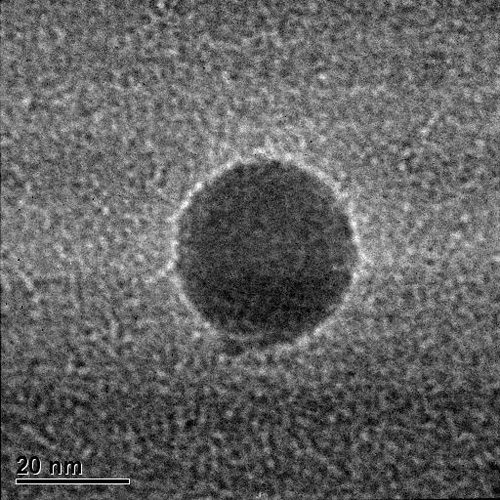

The left picture shows a TEM micrograph of a single Terfenol nanoparticle, deposition onto a film is shown with a SEM picture on the right.

The films were deposited on Si wafer substrates (1.5 by 6.5 mm), and covered with ~300 nm of gold. The film volume was determined from profilometer cross sections taken along the film’s length. They were in fact quite uniform in profile along the entire 6.5 mm length. Assuming a 50% packing density, the film weight was determined based on the film volume and bulk Terfenol-D mass density. These measurements were used to convert the raw magnetometer data into an absolute dipole density (esu/gm).

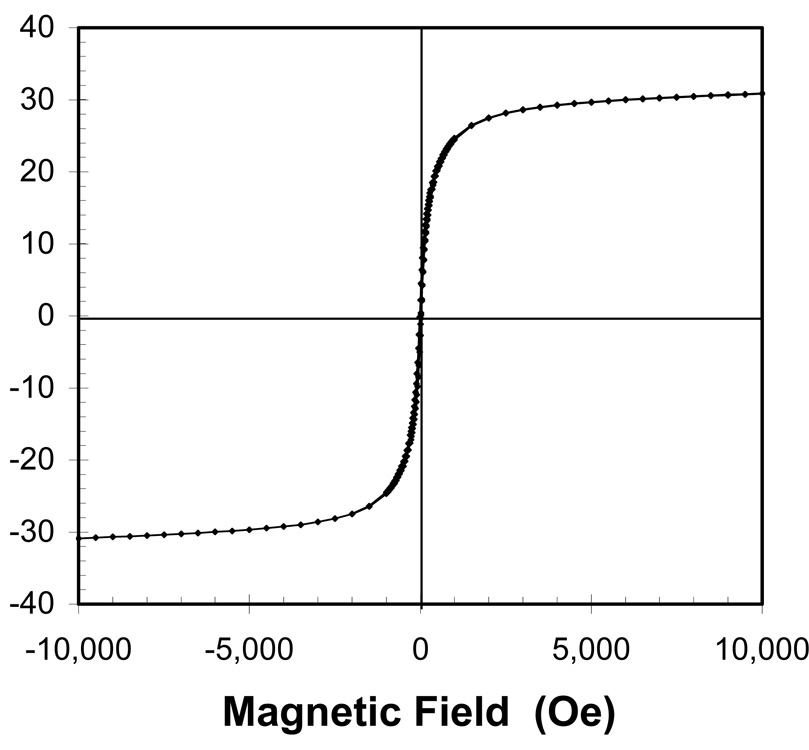

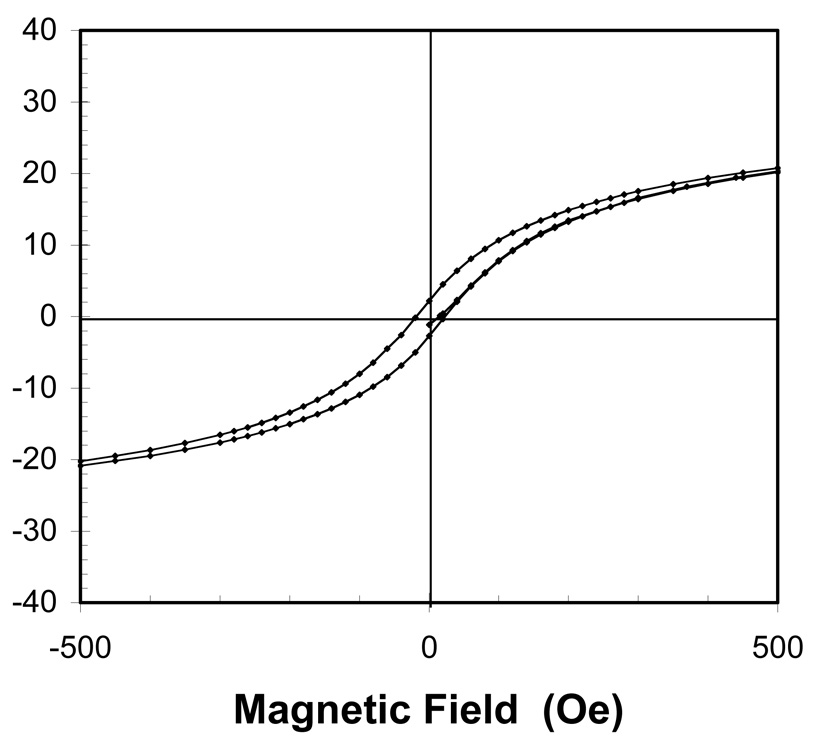

The figure shows SQUID measured M vs. H curves of the deposited film. They are in good agreement with bulk material data. The absolute value of saturation magnetization is 44% of that measured for the bulk material. This value is comparable to films deposited by other techniques such as sputtering (for thinner films). Hysteresis losses are acceptable and the small loop (the right figure shows a blow up of the center region), closely resembles that of the bulk material.

Background information can be found over here: